Valve Heaters

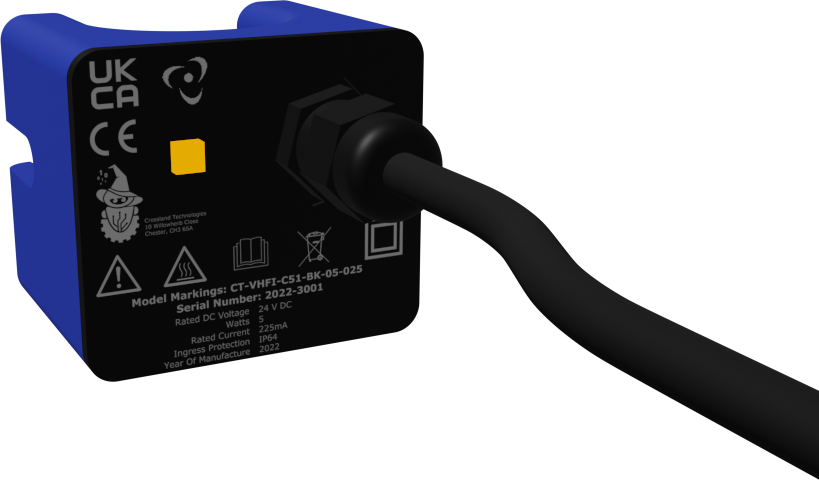

Custom, form fitting, tool free attaching, industrial process valve heaters. Designed and manufactured in the UK, UKCA and CE compliant.

Removable heaters for any valve, any shape.

Industrial Valve Heaters

Designed and manufactured in the UK; UKCA and CE compliant.

Our heaters are manufactured with a durable polyeurathane outer coating making them highly durable, resistant to moisture (IP65) and suitable for challenging industrial environments.

Internally, highly thermally conductive materials are used to distribute heat throughout the heater body, providing even heating across the valve's surface.

We have partnered with the creators of Trivalve, experts in the field of industrial valves, to produce equipment that can be relied upon.

Prevent Ice And Condensation

Reduce maintenance and prolong component life by preventing ice and/or condensation.

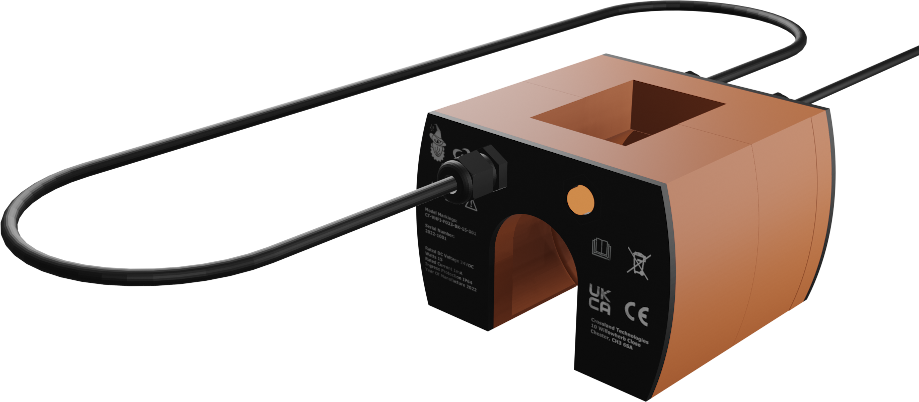

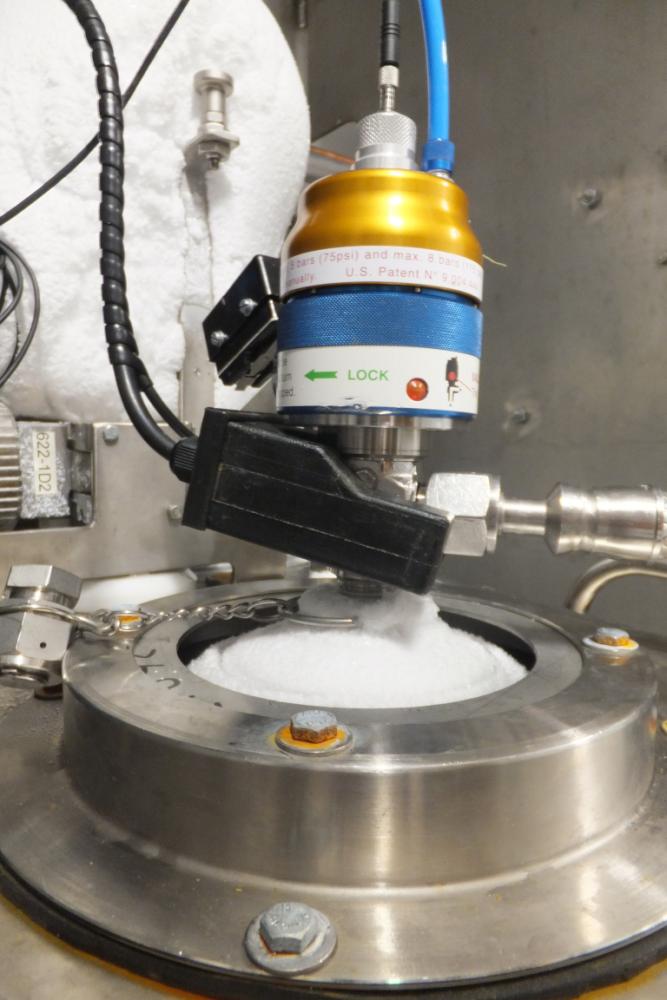

The images show a cryogenic application where a vessel with an automatic isolation valve is maintained at a low temperature.

Over time, the ice on the shoulder of the cylinder builds up; creating a significant mass of ice around the isolation valve.

Not only does this build up add weight to the pipework system but it also increases the rate of maintenance with ice and condensation effecting electrical and mechanical components.

With a valve heater installed the surface temperature of the valve remains above the condensation point, preventing ice from forming.

Tool Free Attachment

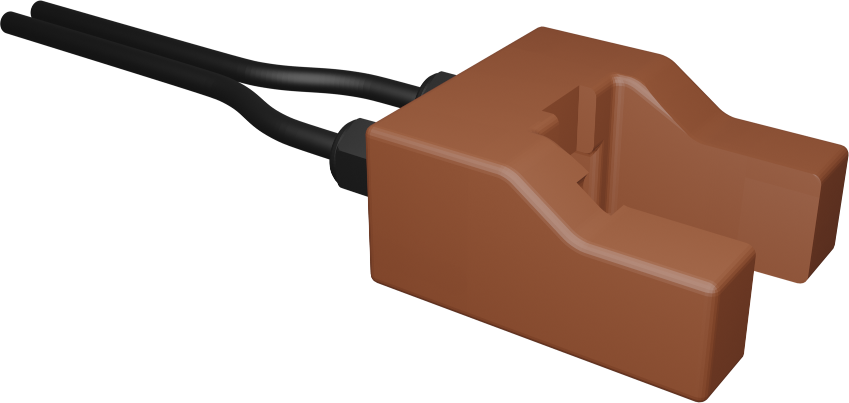

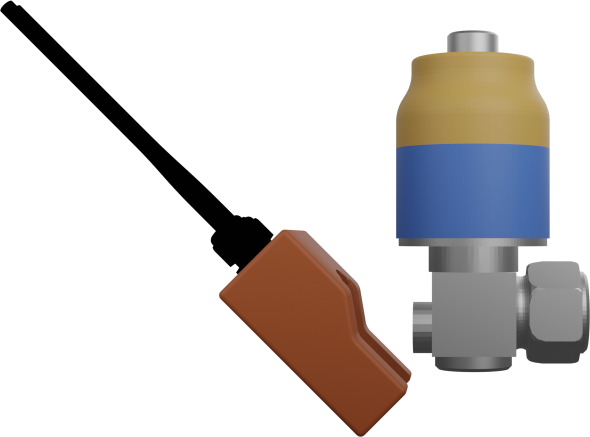

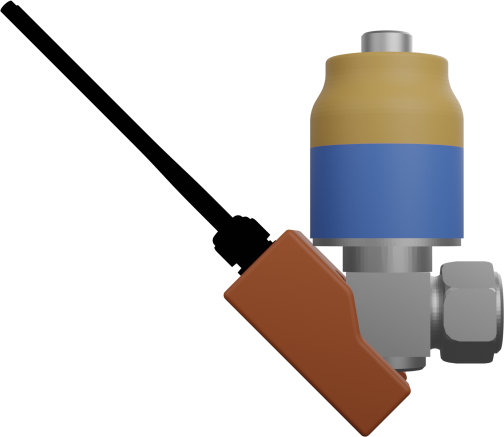

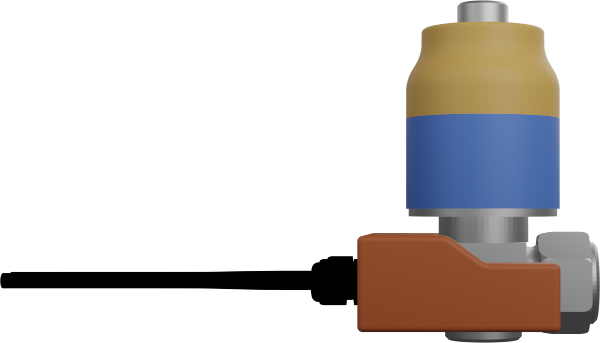

Our form fitting designs not only improve thermal transfer but also enable robust tool free attachment.

Having the ability to attach and remove our heaters without tools not only increases speed of installation but also enables our heaters to be used on removable vessels; where frequent attachment and removal is required.

Our D389S heater, shown here, was designed and manufactured to allow repeated attachment and removal from a cylinder isolation valve. The user's process uses removable vessels and liquid nitrogen to collect material; once filled the vessels are removed and new empty vessels installed.

As shown, the design of the heater makes use of features on the valves body to create a robust mounting method.

Bespoke Service

Every valve and every user's operating requirements are different.

Design

Send or deliver your valve to us (preferred) or provide mechanical drawings. We will produce a design that accommodates your requirements.

Testing

If required, we will undertake testing to determine and/or validate the heater power.

Manufacture

We will manufacture your heaters and ship them to you.

Gallery

Suitable for a wide range of processes our valve heaters assist in preventing internal and external condensation and freezing.

Keeping processes running and maintenance down.

Our valve heaters are individually designed for each valve to produce the best fit.

As shown, the design of the heater makes use of features on the valves body to create a robust mounting method.